Ekstrusi Pipa PVC

-

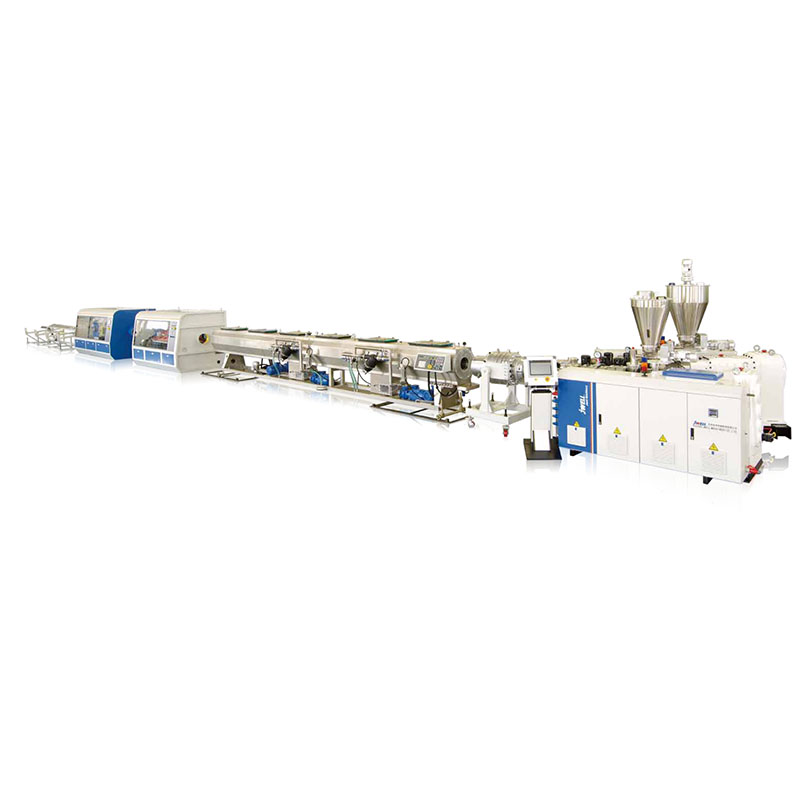

PVC-UH/UPVC/CPVC Pipe Extrusion Line

A macem-macem specifications lan model saka PVC twin-screw extruder bisa gawé pipo saka diameteripun beda lan kekandelan tembok beda.Struktur sekrup sing dirancang khusus kanthi plastikisasi seragam lan output dhuwur.cetakan Extrusion digawe saka baja campuran kualitas dhuwur, saluran aliran internal chrome plating, perawatan polishing, nyandhang lan resistance karat;kanthi lengan ukuran kacepetan dhuwur sing darmabakti, kualitas permukaan pipa apik.Pemotong khusus kanggo pipa PVC nggunakake piranti clamping puteran, sing ora mbutuhake ngganti peralatan kanthi diameter pipa sing beda.Kanthi piranti chamfering, nglereni, chamfering, siji-langkah ngecor.Ndhukung mesin lonceng online opsional.

-

Telung Lapisan PVC Pipe Co-extrusion line

Gunakake loro utawa luwih SJZ seri conical twin screw extruder kanggo ngleksanakake co-extruded telung lapisan PVC pipe.Lapisan sandwich saka pipa kasebut yaiku bahan baku PVC utawa busa PVC kalsium dhuwur.

-

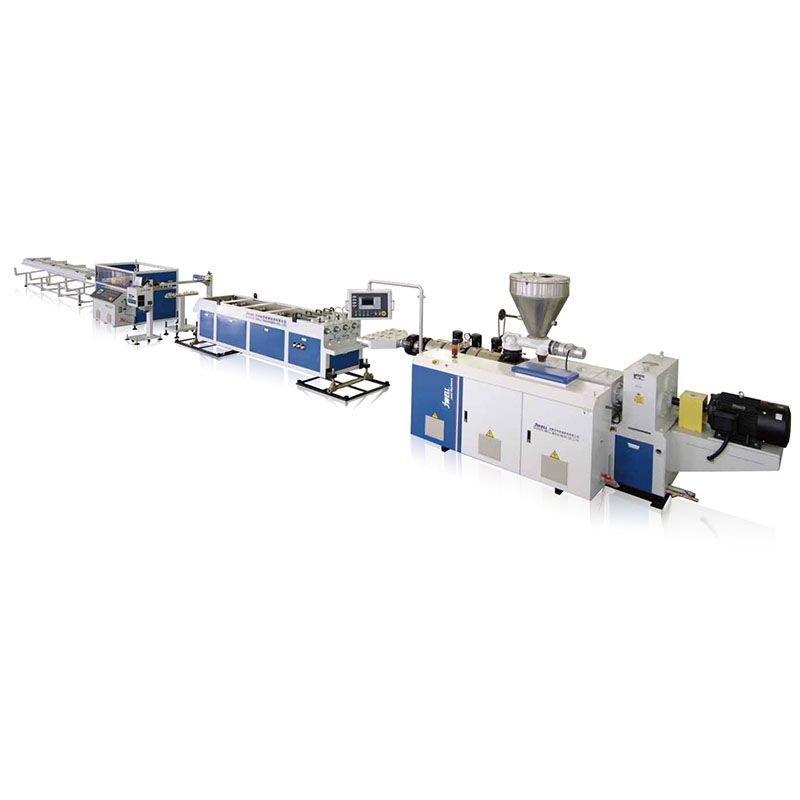

PVC Dual Pipe Extrusion Line

Cocog karo syarat beda diameteripun pipe lan output, ana rong jinis SJZ80 lan SJZ65 khusus twin-meneng extruders opsional;pipe dual die roto-roto distributes output materi, lan kacepetan extrusion pipe cepet plasticized.Kothak cooling vakum pindho efisiensi dhuwur bisa dikontrol kanthi kapisah, lan operasi pangaturan trep ing proses produksi.Mesin pemotong tanpa bledug, kontrol independen stasiun dobel, kacepetan cepet, dawa pemotongan sing akurat.Clamps puteran pneumatik ngilangake kabutuhan kanggo ngganti clamps.Kanthi piranti chamfering opsional.

-

PVC Four Pipe Extrusion Line

Karakteristik kinerja: Jinis paling anyar saka papat PVC electrical bushing line produksi adopts kembar-meneng extruder karo output dhuwur lan kinerja plasticization apik, lan dilengkapi karo jamur optimized kanggo desain path aliran.Papat pipo discharge roto-roto lan kacepetan extrusion cepet.Four tank cooling vakum bisa individu kontrol lan diatur tanpa mengaruhi saben liyane ing proses produksi.